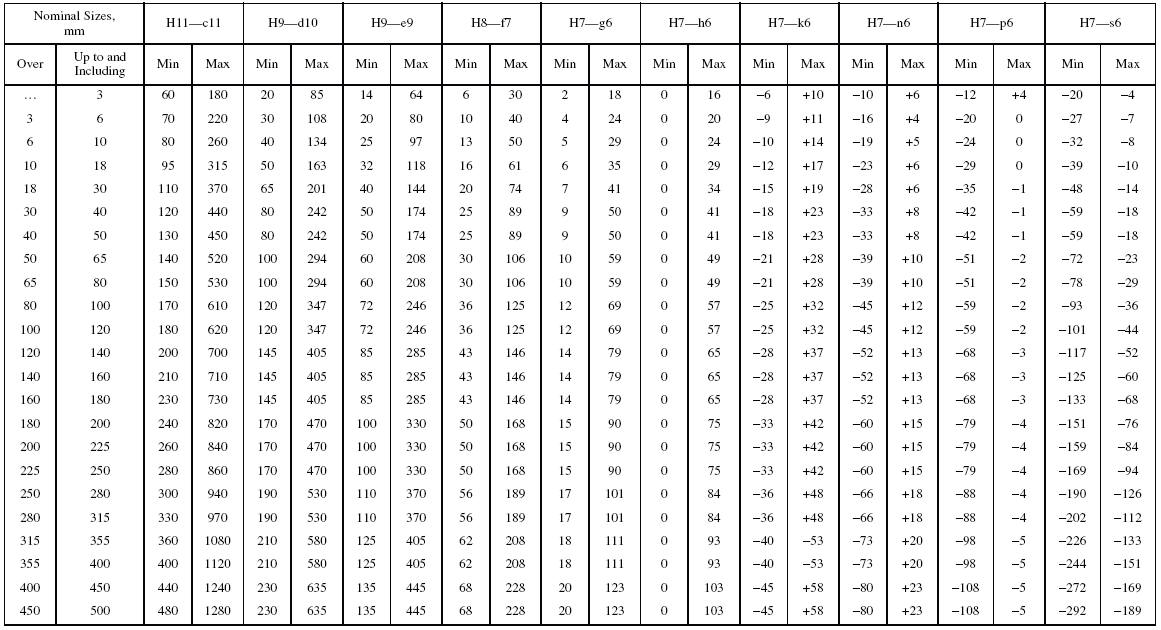

Tolerances of runout reveal circular runout and total runout. Tolerances of angularity covered include angularity, perpendicularity and parallelism. Tolerances of form shown include straightness, flatness, circularity and cylindricity. Geometric characteristic symbols that apply to manufactured Geometric Tolerancing & Coordinate Tolerancing):Ī comprehensice, yet clear explanation with worked examples of all key features. Extreme variations, sizes, form and tolerances are illustrated. Use the Limits, Fits and Tolerances info below either personally or with colleagues to learn, retrain, demonstrate and above all get on.ĭimensional Tolerancing (inc. We also cover Geometric Dimensioning and Tolerances (GD&T) fundamentals for your convenience. It is the difference between the maximum and the minimum limits for the dimension. Tolerance on the other hand is the total amount that a specific dimension is permitted to vary. Thus, the fit between members that move or rotate relative to each other, such as a shaft rotating in a bearing, is considerably different from the fit that is designed to prevent any relative motion between two parts, such as a wheel attached to an axle'. The character of the fit depends upon the use of the parts.

The degree of tightness or looseness between two mating parts that are intended to act together is known as the fit of the parts. 'The extreme permissible values of a dimension are known as limits. In order to understand the terms, a useful succinct definition is provided by McGraw Hill:

0 kommentar(er)

0 kommentar(er)